Revista Académica Arjé. Vol. 8. N° 1. January–June, 2025.

Pedagogy | Technical Education | Technology

National Technical University, Costa Rica

Comprehensive valorization of pineapple cultivation residues for high-value products: a global perspective review

Valorización integral de los residuos del cultivo de piña para productos de alto valor agregado: una revisión desde una perspectiva global

Valorização abrangente dos resíduos do cultivo do abacaxi para produtos de alto valor: uma revisão sob uma perspectiva global

Maynor Alberto Vargas Vargas

Sistema de Gestión de Laboratorios de Investigación, Universidad Técnica Nacional, Costa Rica

https://orcid.org/0000-0002-2264-7417

Arlette Jiménez Silva

Programa Laboratorista Químico para el Aseguramiento de la Calidad, Centro de Calidad y Productividad, Universidad Técnica Nacional, Costa Rica

Received 27-01-2025 | Revised 28-03-2025 | Accepted 117-05-2025

Abstract

Pineapple cultivation generates significant agro-industrial residues, such as peels, crowns, cores, and stubble, which are often discarded despite their potential as valuable raw materials. This review aims to provide a comprehensive assessment of the sustainable valorization of these residues through emerging bio-based technologies. The objective is to critically examine the scientific evidence on their transformation into high-value products in renewable energy, agriculture, bioplastics, and nutraceuticals. Methodologically, this review analyses peer-reviewed literature recently published, selected from academic databases, with emphasis on studies from tropical regions in Asia, Latina America, and Africa. Selection criteria included technological feasibility, environmental relevance, and consistency with circular bioeconomy principles. Results show that pineapple residues, rich in lignocellulosic fibers, sugars, and bioactive compounds, can be converted into bioethanol, biogas, hydrogen, bioplastics, natural dyes, and dietary supplements. In agriculture, biochar and organic fertilizers derived from compost enhance soil health, increase crop productivity, and reduce chemical inputs. Pineapple by-products are also valuable for producing biodegradable packaging, textiles, and natural dyes, offering sustainable alternatives to fossil-based materials. Bioactive compounds such as bromelain and antioxidants extracted from pineapple residues have applications in functional foods, pharmaceuticals, and cosmetics. Natural fibers from crowns and peels are utilized in bioplastics and composite materials, advancing circular economy principles and reducing environmental impacts. Despite their potential, challenges such as technology scalability and market integration remain. By transforming agricultural waste into high-value products, the pineapple industry can contribute to economic growth, environmental preservation, and the development of sustainable industries aligned with circular economy goals.

Keywords: agro-industrial innovation, circular economy, pineapple waste, sustainable agroindustry, waste valorization.

Resumen

El cultivo de la piña genera residuos agroindustriales significativos, como cáscaras, coronas, corazones y rastrojos, que a menudo se descartan a pesar de su potencial como materias primas valiosas. Esta revisión pretende realizar una evaluación integral de la valorización sostenible de estos residuos mediante tecnologías emergentes con fundamento biológico. El objetivo es examinar críticamente la evidencia científica sobre su transformación en productos de alto valor agregado en los sectores de energía renovable, agricultura, bioplásticos y nutracéuticos. Metodológicamente, esta revisión analiza literatura científica revisada por pares y publicada recientemente, seleccionada de bases de datos académicas, con énfasis en estudios realizados en regiones tropicales de Asia, América Latina y África. Los criterios de selección incluyeron viabilidad tecnológica, relevancia ambiental y coherencia con los principios de la bioeconomía circular. Los resultados muestran que los residuos de piña, ricos en fibras lignocelulósicas, azúcares y compuestos bioactivos, pueden convertirse en bioetanol, biogás, hidrógeno, bioplásticos, colorantes naturales y suplementos dietéticos. En agricultura, el biocarbón y los fertilizantes orgánicos a base de compost mejoran la salud del suelo, aumentan la productividad agrícola y reducen el uso de insumos químicos. Los subproductos de la piña también son valiosos para la producción de envases biodegradables, textiles y tintes naturales, ofreciendo alternativas sostenibles a materiales derivados del petróleo. Compuestos bioactivos como la bromelina y los antioxidantes extraídos de los residuos de piña tienen aplicaciones en alimentos funcionales, productos farmacéuticos y cosméticos. Las fibras naturales de coronas y cáscaras se utilizan en bioplásticos y materiales compuestos, promoviendo los principios de la economía circular y reduciendo los impactos ambientales. A pesar de su potencial, persisten desafíos como la escalabilidad tecnológica y la integración en el mercado. Al transformar los residuos agrícolas en productos de alto valor, la industria piñera puede contribuir al crecimiento económico, la preservación ambiental y el desarrollo de industrias sostenibles alineadas con los objetivos de la economía circular.

Palabras clave: agroindustria sostenible, economía circular, innovación agroindustrial, residuos de piña, valorización de residuos.

Resumo

O cultivo do abacaxi gera resíduos agroindustriais significativos, como cascas, coroas, miolos e restos de colheita, que muitas vezes são descartados apesar de seu potencial como matérias-primas valiosas. Esta revisão tem como objetivo realizar uma avaliação abrangente da valorização sustentável desses resíduos por meio de tecnologias emergentes com base biológica. O objetivo é examinar criticamente as evidências científicas sobre sua transformação em produtos de alto valor agregado nos setores de energia renovável, agricultura, bioplásticos e nutracêuticos. Metodologicamente, esta revisão analisa literatura científica revisada por pares e publicada recentemente, selecionada a partir de bases de dados acadêmicas, com ênfase em estudos realizados em regiões tropicais da Ásia, América Latina e África. Os critérios de seleção incluíram viabilidade tecnológica, relevância ambiental e coerência com os princípios da bioeconomia circular. Os resultados mostram que os resíduos do abacaxi, ricos em fibras lignocelulósicas, açúcares e compostos bioativos, podem ser convertidos em bioetanol, biogás, hidrogênio, bioplásticos, corantes naturais e suplementos dietéticos. Na agricultura, o biocarvão e os fertilizantes orgânicos à base de composto melhoram a saúde do solo, aumentam a produtividade agrícola e reduzem o uso de insumos químicos. Os subprodutos do abacaxi também são valiosos para a produção de embalagens biodegradáveis, têxteis e corantes naturais, oferecendo alternativas sustentáveis aos materiais derivados do petróleo. Compostos bioativos como a bromelina e antioxidantes extraídos dos resíduos de abacaxi têm aplicações em alimentos funcionais, produtos farmacêuticos e cosméticos. As fibras naturais das coroas e cascas são utilizadas em bioplásticos e materiais compósitos, promovendo os princípios da economia circular e reduzindo os impactos ambientais. Apesar do seu potencial, persistem desafios como a escalabilidade tecnológica e a integração no mercado. Ao transformar os resíduos agrícolas em produtos de alto valor, a indústria do abacaxi pode contribuir para o crescimento econômico, a preservação ambiental e o desenvolvimento de indústrias sustentáveis alinhadas aos objetivos da economia circular.

Palavras-chave: agroindústria sustentável, economia circular, inovação agroindustrial, resíduos de abacaxi, valorização de resíduos.

Introduction

Pineapple cultivation (Ananas comosus) is one of the main agricultural activities in tropical and subtropical countries, significantly contributing to international trade, job creation, and the economic livelihood of rural communities (Alejo Jeronimo et al., 2023). Leading producers in 2022 included Indonesia, the Philippines, and Costa Rica, with outputs of 3,156,576, 2,944,260, and 2,92,937,807 metric tons, respectively (FAOSTAT, 2023). While valued for its flavor, nutrition, and versatility in food industries, the sector faces a major challenge: managing waste from cultivation and processing (Salve & Ray, 2020).

Up to 40% of processed pineapple weight becomes waste, including peels, crowns, cores, and stubble as shown on Table 1.

Table 1.

Main global pineapple producers and estimated waste generation potential (2022)

|

Country |

Production (TM) |

Cultivated area (ha) |

Yield (kg/ha) |

Estimated waste (million TM, as 40%) |

|---|---|---|---|---|

|

Indonesia |

3,156,576 |

23,550 |

134,036.6 |

1.26 |

|

Philippines |

2,944,260 |

69,149 |

42,578.6 |

1.18 |

|

Costa Rica |

2,937,807 |

40,000 |

73,445.2 |

1.18 |

|

China |

2,468,740 |

78,226 |

31,559.0 |

0.99 |

|

Brazil |

2,387,393 |

63,943 |

37,336.3 |

0.95 |

Source: Data from FAOSTAT (2023) based on national reports.

Approximately 80% of pineapple parts are discarded during processing, transportation, and storage, despite their richness in fibers, sugars, and bioactive compounds (Aili-Hamzah et al., 2021; Meena et al., 2022). According to Eixemberg et al. (2024), pineapple field residues, mainly leaves and stems, can amount to 80 to 150 tons per hectare per harvest. These residues are typically returned to the soil to replenish nutrients, with composting being the preferred method over burning, as it preserves the nutrient content.

Historically underutilized, these by-products are often discarded in landfills, contributing to methane emissions and environmental degradation (Sarangi et al., 2023). However, they hold potential as sustainable resources for bioenergy, bromelain, cellulose nanocrystals, biodegradable packaging, and products like vinegar and wine (Aili-Hamzah et al., 2021). The idea of converting agricultural waste into industrial inputs takes on particular relevance here. In the case of pineapple residues, their current underuse reflects more than just inefficiency. It reveals a disconnect between waste management and innovation. As a consequence, valuable bioresources are left to decay, releasing methane, a highly potent greenhouse gas. Moreover, when residues are indiscriminately dumped onto soil, they may contribute to nutrient imbalances, localized contamination, and even disrupt native soil biodiversity (Sarangi et al., 2023).

Circular economy principles provide more than just a theoretical framework, offering tangible strategies to turn agricultural waste into profitable solutions. In the case of pineapple residues, exploiting their potential does not only reduce environmental burdens, it also opens possibilities for rural entrepreneurship, local processing, and new income sources for producers and small industries. This change from waste to resource, as noted by Chaves et al. (2024), exemplifies how sustainability can be operationalized in real economic contexts.

Pineapple residues, rich in lignocellulosic fibers, sugars, and bioactive compounds, present diverse opportunities for value-added applications (Amores-Monge et al., 2022). For example, fibers from pineapple crowns are used to produce Piñatex®, a plant-based leather substitute widely adopted in the fashion industry, developed by Dr. Carmen Hijosa (Dhanda et al., 2024). Additionally, pineapple peels, rich in antioxidants and fermentable sugars, are now being transformed into bioethanol, biogas, and biochar, contributing to both renewable energy generation and sustainable agriculture (Sarangi et al., 2023). Residues also contain bromelain, a proteolytic enzyme with potential applications in sectors as diverse as food processing, pharmaceuticals, and cosmetics (Kansakar et al., 2024).

By integrating environmental and economic perspectives, this approach does more than reducing ecological impacts, since it promotes innovation and opens more opportunities for sustainable development in multiple sectors. Notably, technological advances sucg as pyrolysis for biochar production (Srikhaow et al., 2023), steam distillation for extracting essential oils (Hikal et al., 2021), and fermentation for bioethanol production (Chintagunta et al., 2017), have proven effective in improving the use of resources, stimulating job creation, and contributing to more resilient local economies, especially in rural areas.

Besides its technical and economic potential, the complete valorization of pineapple residues aligns with Sustainable Development Goals (SDGs) focused on reducing agricultural waste and promoting responsible production and consumption systems, climate action, and industrial innovation, as noted by Sarangi et al. (2023). This approach also supports economic diversification while mitigating the environmental of intensive agricultural production (Mutjaba et al., 2023).

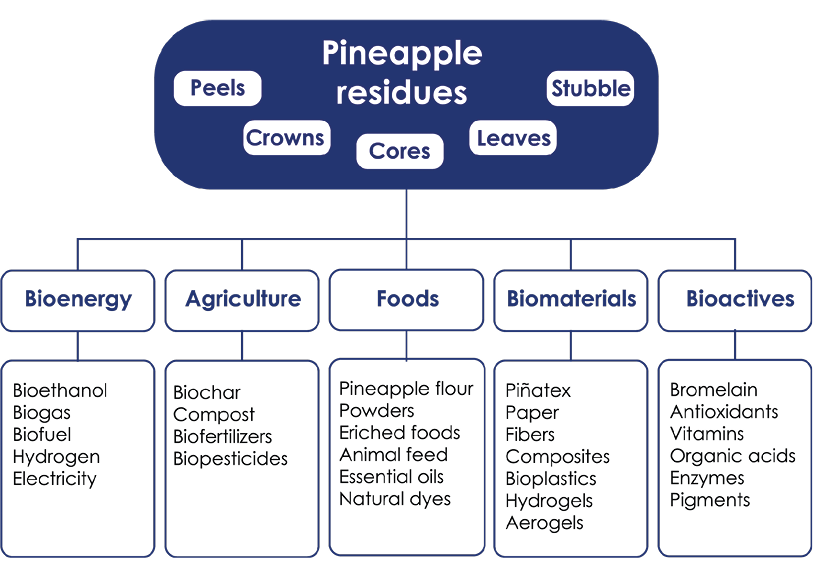

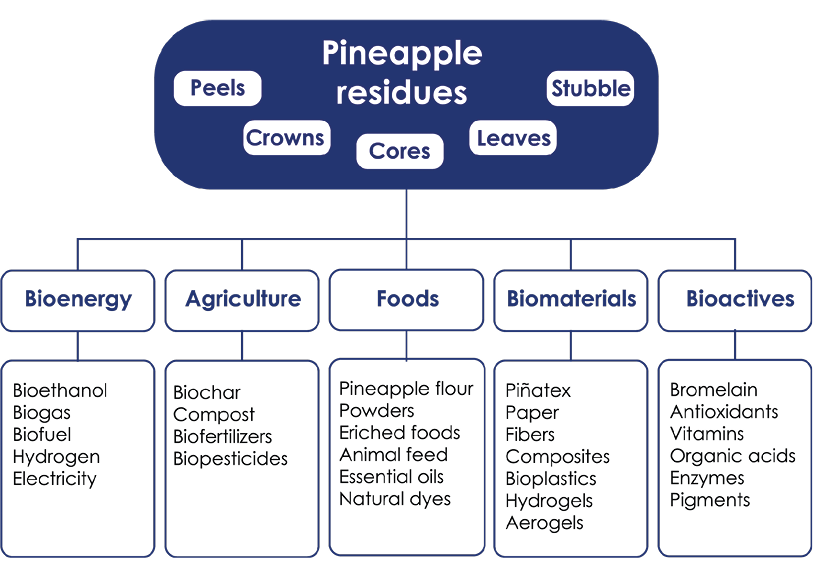

Figure 1.

Valorization Pathways of Pineapple Agro-Industrial Residues

Source: Prepared by the authors based on literature review (2025).

This article provides an overview of recent strategies for the utilization of pineapple cultivation residues, with special attention to their processing methods, applications, and benefits. The examples presented, from bio-based textiles and renewable energy sources to nutritional supplements and cosmetic products, demonstrate the potential of these residues in multiple sectors, that not only addresses agricultural waste challenges but also creates economic opportunities and support social development. Through technological innovation and collaboration, the transformation of agricultural waste into valuable resources may become an important contribution to global sustainability goals.

Methodological approach

To explore the current state of sustainable pineapple residue utilization, this review was conducted with a global perspective. It is based on the analysis of peer-reviewed scientific publications mainly released between 2018 and 2024. The literature was selected from major academic databases such as Scopus, Web of Science and ScienceDirect, focusing on technological relevance, feasibility of application, and alignment circular bioeconomy principles. Compared to earlier reviews, this work offers a more integrated perspective, including innovations in materials science, renewable energy, biotechnology, and sustainable agriculture. The purpose of this synthesis is to offer a structured overview that may serve as a reference for future research, policy-making, and innovation inniatives related to agricultural waste valorization, especially in tropical regions.

1. Circular approach to waste utilization

The comprehensive utilization of pineapple cultivation and processing residues plays a strategic role in promoting the circular economy, which aims to improve resource efficiency while minimizing environmental impacts (Figge et al., 2023; Kirchherr et al., 2023). Through the application of chemical, biological, and physical processes, as shown later on Table 2, these organic by-products can be converted into high-value materials, contributing both to sustainable waste management and economic development (Mutjaba et al., 2023; Yang et al., 2023).

Pineapple residues, such as peels, crowns, cores, and stubble, represent an underutilized resource despite their richness in valuable compounds (Salve & Ray, 2020). Industrial pineapple processing generates substantial waste: peels represent about 30%, pomace 50%, cores 7%, and crowns 13% of the fruit mass, making up 25–35% of the total fruit weight (Banerjee et al., 2018). These lignocellulosic materials, composed primarily of cellulose, hemicellulose, and lignin, can be transformed into biodegradable paper, biopolymers, and sustainable textiles, offering eco-friendly alternatives to fossil-derived products (Mujtaba et al., 2023; Chaves et al., 2024).

Saberi Riseh et al. (2024) highlight the potential of agricultural residues, including pineapple waste, as a promising source of cellulose, a renewable and biodegradable biopolymer. When efficiently extracted, cellulose can be converted into nanomaterials and nanocomposites applicable in fields such as agriculture, energy, medicine, and industrial manufacturing. Reusing these residues not only helps to reduce environmental pollution but also supports sustainable innovation by generating ecological and economic value.

From a chemical perspective, pineapple residues can undergo enzymatic or acid hydrolysis to release sugar monomers. These monomers are then fermented to produce bioethanol, a renewable fuel that supports cleaner energy strategies (Vasić et al., 2021). In parallel, pineapple waste contains bioactive compounds such as antioxidants and bromelain, a proteolytic enzyme widely applied in food processing, cosmetics, and pharmaceuticals (Salve & Ray, 2021). According to Banerjee et al. (2018), these residues also have the potential to generate value-added chemicals including xylitol, lactic acid, and succinic acid, alongside bromelain for nutritional and therapeutic use. This integrated approach, often referred to as biorefinery model, contributes to circular economy goals by transforming agricultural waste into useful industrial inputs. However, barriers such as logistical complexity, limited market adoption, and scaling remain important issues that require further research and optimization. In this context, the role of agriculture and agro-industry is essential, not only as providers of raw biomass, but also as active participants in converting residues into valuable products (Wagh et al., 2024).

From a biological perspective, pineapple residues can be used in anaerobic digestion, where microorganisms decompose organic matter in the absence of oxygen to produce biogas, a renewable mixture of methane and carbon dioxide (Rabiu et al., 2018; Singh et al., 2023). This same process produces biofertilizers rich in nutrients, which help improve soil and support sustainable agriculture (Unnikrishnan & Ramasamy, 2022).

On the physical side, technologies like pyrolysis are applied to convert lignocellulosic waste into biochar. This carbon-based material improves soil moisture and nutrient retention and also helps to reduce atmospheric carbon, contributing to climate change mitigation (Bohari et al., 2020; Yang et al., 2023).

These scientific approaches, chemical, biological, and physical, are summarized in Table 2, along with the main products and applications areas such as agriculture, energy, food, pharmaceuticals, and sustainable materials.

Table 2.

Scientific Approaches to the valorization of pineapple residues

|

Process |

Main techniques |

Example products |

Application Sectors |

|---|---|---|---|

|

Chemical |

- Acid hydrolysis |

- Bioethanol |

- Biofuels |

|

- Enzymatic hydrolysis |

- Lactic acid |

- Food |

|

|

- Fermentation |

- Citric acid |

- Pharmaceuticals |

|

|

Biological |

- Anaerobic digestion |

- Biogas |

- Agriculture |

|

- Composting |

- Compost |

- Energy |

|

|

- Fermentation |

- Liquid fertilizers |

- Soil improvement |

|

|

Physical |

- Pyrolysis |

- Biochar |

- Agriculture |

|

- Grinding |

- Paper Pulp |

- Packaging |

|

|

- Drying |

- Fiber textiles |

-Textiles |

|

|

- Solvent extraction |

- Bioactives |

- Nutraceuticals |

|

|

- Bromelain |

Source: Prepared by the authors based on literature review (2025).

From an agro-industrial engineering perspective, effective residue utilization depends on integrated systems for collecting, processing, and storing waste. For example, pineapple crowns can be processed through crushing and washing to obtain strong and flexible fibers. After chemical treatments such as alkalization and bleaching, these fibers are appropriate for producing textile materials with mechanical properties similar to leather (Ramli et al., 2017). One well-known application is Piñatex®, a biodegradable leather alternative used in the fashion sector (Dhanda et al., 2024).

Biodegradable paper can be produced from pineapple peels and crowns using a combination of chemical and physical processes (Mendoza Cisneros et al., 2020). The resulting pulp is pressed and dried into thin sheets, avoiding the use of dangerous chemical additives commonly used in paper production (Velázquez et al. 2021). This eco-friendly material is used in packaging and various types of stationery (Moya et al., 2023).

In the energy sector, pineapple residues rich in sugars and volatile compounds are fermented to produce bioethanol and biogas. The remaining solids may be reused as compost or organic fertilizer, combining principles of chemistry, microbiology, and thermal processed to support sustainable waste conversion (Chintagunta et al., 2017).

The circular economy approach applied to pineapple residues combines scientific and technological tools to reduce environmental impact while creating economic value. By using their physical, chemical, and biological characteristics, it is possible to develop high-value products that contribute to closing production cycles and promoting sustainable industrial development. The success of this model depends on interdisciplinary efforts of the application of green chemistry, agro-industrial engineering, and biotechnology (Saini et al., 2023).

2. Innovations in sustainable materials

Pineapple residues contain lignocellulosic fibers and natural compounds that make them a potential raw material for developing biodegradable materials and eco-friendly textiles (Amores-Monge et al., 2022; Sethupathi et al., 2024; Yousuf et al., 2020). Notable products include the following:

2.1. Textile fiber from pineapple crowns

Pineapple leaf fiber (PALF), once treated as agricultural waste, is now recognized for being renewable, biodegradable, and cost-effective. It has shown good potential as a reinforcement agent in composites, improving mechanical strength while reducing the use of synthetic polymers. Its applications are expanding into textiles, cosmetics, medical products, and biopolymer coatings. PALF’s versatility extends to industries such as textiles, cosmetics, medicine, and biopolymer coatings (Sethupathi et al., 2024).

Pineapple crowns (PC) represent an underused source of strong, flexible fibers with promising applications in the textile sector (Kumar et al., 2024). The extraction process typically includes mechanical crushing, washing to eliminate impurities, and chemical treatments to improve structural properties for specific uses. Fernandes Pereira et al. (2021) described a method to obtain high-quality fibers: fresh crowns are dried at 60 °C for 24 hours, cut into small pieces (2 - 4 cm), and ground to 35 mesh size. Material larger than 0.5 mm is reground to ensure uniformity.

Due to their mechanical and stability, these fibers are gaining attention as sustainable alternatives in various applications. Their use not only reduces environmental impact, but also adds value to agriculture residues that are often discarded.

2.2. Biodegradable paper made from fibers

Using pineapple peels and crowns to produce biodegradable paper is a promising way to valorize lignocellulosic residues. Pineapple leaf fiber (PALF), with its high cellulose content and good mechanical strength, provides a renewable alternative to wood pulp in the paper and textile industries (Moya et al., 2023). Replacing wood with PALF helps reduce deforestation, supports sustainable farming, and increases the value of pineapple cultivation, offering additional income for producers within a circular economy framework.

This production process includes shredding the residues, mixing the pulp with water, and then pressing and drying it into thin sheets, without using dangerous chemicals like bleaches This makes the paper suitable for sustainable packaging and stationery (Asoba et al., 2023). According to Moya et al. (2023), enzymatic processing with xylanase produces a whiter and heavier paper, though with slighter lower mechanical resistance. Similarly, Mahatme et al. (2018) highlight PALF as a promising raw material for paper production due to its high lignin and cellulose content.

Biodegradable paper derived from pineapple waste can be used for eco-packaging, food wrapping, office materials, and decorative products. As noted by Málaga & Velázquez (2020), pineapple stubble contains around 8% lignin and 66% holocellulose (dry basis), making it a viable input. This approach reduces reliance on virgin fibers and helps turn agricultural waste into useful materials, while contributing to more sustainable production cycles (Asoba el al., 2023; Moya et al., 2023).

2.3. Reinforced fibers for composite materials

Fibers from pineapple crowns and stems are lightweight, resilient, and suitable for producing composite materials. When combined with natural or synthetic polymers through molding or extrusion, they result in durable and environmentally friendly structures (Santulli et al., 2022).

Khan et al. (2024a) observed that the mechanical performance of pineapple leaf fiber (PALF) corresponds well with stress prediction models used in composite analysis. These materials are biodegradable or recyclable, and are already used in the construction, automotive, and furniture industries as sustainable alternatives to glass-reinforced plastics (Asim et al., 2015; Mohammadi et al., 2023; Uma Devi et al., 2012).

To address the cost of bio-based polymers such as polylactic acid (PLA), natural reinforcements like PALF offer a viable solution. PALF is abundant, low-cost, and renewable, with a high cellulose content (70–82%) and favorable structural properties, such as a low spiral angle (14%), contributing to strong, lightweight composites (Omar et al., 2023).

Akkan (2023) describes Piñatex® as an innovative textile made from pineapple crown fibers, offering a biodegradable alternative to animal leather. Its production requires less water and energy, aligning with circular economy goals and reducing agricultural waste.

Namphonsane et al. (2023) also developed rigid biodegradable foams using starch pineapple stems and leaf cellulose. These foams, which exhibit high water absorption rates (150–200%), degrade within 15 days and may be used in single-use packaging.

The use of pineapple residues in composite materials contributes to cleaner production and supports innovation in material science (Sarangi et al., 2023). For instance, Velázquez and Málaga (2019) created a bio-based leather substitute from pineapple leaf fibers, combining environmental efficiency with economic value.

Table 3 summarizes a list of key materials derived from pineapple residues and their applications.

Table 3.

Sustainable materials derived from pineapple

|

Material type |

Residue |

Process type |

Application |

References |

|---|---|---|---|---|

|

Textile fiber (PALF) |

Leaves, crowns |

Mechanical ex-traction, alkali pretreatment |

Fabrics, textiles, composites, bio-coatings |

Sethupathi et al. (2024); Kumar et al. (2024); Fernan-des Pereira et al. (2021). |

|

Biodegradable paper |

Peels, stubble |

Pulping, enzymatic or chemical processing |

Packaging, labels, office stationery |

Moya et al. (2023); Asoba et al. (2023); Mahatme et al. (2018); Málaga & Velázquez (2020) |

|

Bio-based leather |

Crowns |

Fiber isolation + coating layering |

Vegan leather for fashion and ac-cesories |

Dhanda et al. (2024); Akkan (2023); Velázquez & Málaga (2019). |

|

Reinforced composites |

PALF + PLA or clays |

Molding, extru-sion, PLA integra-tion |

Vehicle interiors, construction pan-els, trays |

Omar et al. (2023); Namp-honsane et al. (2023); Sa-rangi et al. (2023). |

|

Rigid biode-gradable foams |

Stems, non-fibrous leaves |

Starch extraction + pressing |

Sigle-use trays, containers |

Namphonsane et al. (2023) |

|

Cellulose nano-crystals |

Crown leaf fi-bers |

Alkaline pretreat-ment + acid hy-drolysis |

Biofilms, packag-ing, biomedical applications |

Fitriani et al. (2021b); Soa-res-Faria et al. (2020). |

Source: Prepared by the authors based on literature review (2025).

3. Renewable energy from organic waste

Pineapple residues offer promising options for clean energy generation and can support the shift toward renewable energy while improving agricultural sustainability (Aili-Hamzah et al., 2021).

3.1. Bioethanol from residues

Bioethanol is a liquid biofuel obtained by fermenting sugars found in pineapple waste, especially in peels and cores. The process involves shredding the material, hydrolyzing it to release fermentable sugars, and applying specific yeasts to convert them into ethanol, which is then purified by distillation (Chintagunta et al., 2017).

Bioethanol can be used in internal combustion engines, either blended with gasoline or as a main fuel in modified engines (Awogbemi et al., 2021). Mgeni et al. (2024) showed that pineapple juice fermented with bakery yeast offers a practical method for ethanol production without competing with food crops.

Enzymatic pretreatments, such as cellulase from Trichoderma harzianum, have been shown to improve sugar release, making the process more efficient and economically viable (Casabar et al., 2019).

3.2. Biogas from anaerobic digestion

Pineapple waste decomposes quickly, which makes proper management essential to prevent environmental damage (Aili-Hamzah et al., 2021). Anaerobic digestion is a well-established method that breaks down organic matter without oxygen, producing biogas mainly composed of methane (CH4) and carbon dioxide (CO2). Methane can be used to generate heat or electricity (Jehan et al., 2017).

Thanks to the high carbohydrate content, pineapple waste is a suitable substrate biogas production. For example, ensiled pineapple peels produced 0.67 m3 of biogas per kg of volatile solids, with 65% methane, higher than typical yields from cow dung (0.2–0.5 m3 per kg of dry matter) (Banerjee et al., 2018).

Combining pineapple residues with cow dung in a 2:1 ratio, and adding nutrients such as magnesium, nitrogen, and phosphorus, creates a stable slurry that can be used as an organic fertilizer (Unnikrishnan & Ramasamy, 2022).

Anaerobic digestion is flexible and can be applied at small or large scale. Adjusting key factors like temperature, retention time, and carbon-to-nitrogen ratio helps improve gas yields and process efficiency (Otieno et al., 2023).

3.3. Hydrogen production via gasification

Gasification is a thermochemical method that converts lignocellulosic waste, such as pineapple crowns and stubble, into synthesis gas (syngas) under limited oxygen conditions (Aili Hamzah et al., 2021). Syngas contains hydrogen, carbon monoxide, and methane (Santos et al., 2023). Hydrogen can be separated from syngas using technologies like pressure swing adsorption (PSA) or selective membranes (Kolaczkowski et al., 2023).

The hydrogen obtained can be used in fuel cells to generate electricity with no direct emissions. It is also important for industrial and transport uses. Although gasification requires significant investment, it offers a clean, carbon-neutral pathway for hydrogen production from agricultural waste (Malik et al., 2023).

3.4. Bioelectricity from Microbial Fuel Cells (MFCs)

Microbial fuel cells (MFCs) offer an innovative technology to produce electricity from pineapple processing wastewater. Microorganisms in the system break down organic compounds, releasing electrons that generate an electric current (Rojas-Flores et al., 2022). MFCs combine renewable energy production with wastewater treatment. Although they are still under development for larger applications, they show promise for low-cost, small-scale systems that recover energy from agro-industrial waste (Naha et al., 2023).

4. Sustainable agriculture and soil improvement

The use of pineapple residues in agriculture offers dual advantage: reducing organic waste and improving soil health (Kamaruddin et al., 2022). Peels, crowns, and stubble are rich in organic matter, nutrients, and bioactive compounds, making them suitable for soil restoration and crop productivity enhancement.

These by-products can be transformed into compost, biochar, liquid fertilizers, biopesticides, hydroponic substrates, and biopesticides. Their use promotes sustainable farming practices, contributes to climate change mitigation, and helps close nutrient cycles (Paz-Arteaga et al., 2024).

4.1. Organic fertilizers or enriched compost

Aerobic composting is a common method to convert pineapple residues into nutrient-rich organic fertilizer (Sukri et al., 2023). This involves mixing the waste with manure or crop residues and allowing microbial decomposition under controlled conditions. The final compost improves soil structure, water retention, and nutrient content (Sossa et al., 2024).

Enriched compost promotes microbial activity and soil fertility, making it especially valuable for organic farming systems (Gunawardena & Lokupitiya, 2024; Wang et al., 2022). It also contributes to carbon sequestration and reduces reliance on synthetic inputs, mitigating climate change (Bhatia et al., 2023).

4.2. Biochar from lignocellulosic residues

Biochar is produced by heating pineapple residues in the absence of oxygen (pyrolysis). This carbon-rich, porous material improves soil moisture retention and nutrient availability, especially in degraded or dry soils (Kabir et al., 2023; Khan et al., 2024b).

When combined with compost or other organic amendments, biochar enhances soil quality through synergistic effects, making pineapple residues a valuable input for regenerative agriculture (Frimpong et al., 2021; Kabiri, 2024). Hanyabui et al. (2024) reported that applying biochar together with compost or NPK fertilizer significantly improved plant height, leaf number, and fruit yield in pineapple cultivation compared to using these treatments alone. In addition, biochar reduces nutrient leaching, improves fertilizer use efficiency, and functions as a long-term carbon sink, helping to mitigate greenhouse gas emissions (Layek et al., 2022; Shoudho et al., 2024; Yang et al., 2023).

4.3. Organic liquid fertilizers

Liquid waste from pineapple processing, such as juices or effluents, can be fermented to produce liquid fertilizers. These contain nutrients in soluble forms that plants absorb easily (Abidin et al., 2024). Their application is useful in precision and organic farming. Adding beneficial microorganisms further improves soil microbiota and increases crop resilience under stress conditions (Wei et al., 2024).

4.4. Natural biopesticides from pineapple residue extracts

Pineapple residues contain bioactive compounds like phenolic acids and flavonoids with antimicrobial and antioxidant properties (Meena et al., 2022). Extracted through maceration or distillation, they are used to produce natural biopesticides that are biodegradable and safer than synthetic chemicals. These products are friendly to pollinators and aquatic environments and align with circular economy principles (Ayilara et al., 2023; Tripathi, 2023).

5. Functional nutrition and supplements

Pineapple residues contain valuable nutritional and functional compounds that can be transformed into supplements for human and animal use through agro-industrial processes (Lalhruaitluangi & Mandal, 2024 ; Polania Rivera et al., 2023; Roda & Lambri, 2019). This approach offers a sustainable way to repurpose organic waste while supporting the development of functional foods aimed at improving health and nutrition (Paz-Arteaga et al., 2024).

Solid fractions from stems and peels are rich in structural carbohydrates, dietary fiber, sugars, vitamins, and polyphenols (Campos et al., 2020). Hemung et al. (2022) successfully extracted vitamins A, C, and E from pineapple peels. Phenolic compounds, such as gallic, chlorogenic, and caffeic acids, can be obtained using solvent-based methods, including cold percolation with methanol, n-hexane, or mixed solvent (Leonardo et al., 2018). Oils and fatty acids have also been recovered as hydrosols, with reported yields ranging from 71% to 81% (Mohamad et al., 2019).

The bioactive potential of pineapple residues has been well documented, emphasizing their relevance for developing health-oriented products and wellness applications (Sarangi et al., 2023).

5.1. Flour from peels and cores for animal feed

Pineapple peels and cores, often discarded, are now recognized as useful raw materials for animal feed. Nearly 60% of fresh pineapple (peels, pulp, crowns, and leaves) is considered waste, yet these parts are rich in fiber, protein, sugars, ascorbic acid, and moisture (Sukri et al., 2023).

Low-temperature dehydration preserves the nutritional content and prevents the loss of essential compounds (Rahman & Yang, 2018). For example, Gomes dos Reis et al. (2023) dried layers of pineapple peels at 50-80 °C, obtaining a flour with low water activity and acidity, ideal for storage. Once milled, this flour is rich in fiber, complex carbohydrates, and minerals such as calcium, potassium, magnesium, along with phenolic compounds (Mala et al., 2024). This type of flour has been incorporated into livestock and poultry feed, where it contributes to improved gut health and digestion by regulating intestinal flora and preventing digestive disorders (Idayanti et al., 2021). Rahman and Yang (2018) also found that pineapple leaf powder (PLP) enhances broilers performance and helps balance gut microorganisms, offering energy and nutrients that support animal growth. Similarly, Linh et al. (2024) reported that including PLP in the diet of crossbred chickens between 5 and 12 weeks of age improved growth rates.

In aquaculture, powdered pineapple peel (PAPP) has also shown positive effects. Van Doan et al. (2021) found that supplementing tilapia diets 10 g/kg of PAAP improved growth, feed efficiency, and survival rates against Streptococcus agalactiae. Likewise, Sukri et al. (2022) evaluated the effect of pineapple waste on Nile tilapia, reporting that inclusion levels up to 30% enhanced growth performance, flesh quality, and color.

Using pineapple residues in feed formulations promotes sustainable production by reducing dependence on commercial feed and optimizing the use of agricultural by-products, with both environmental and economic benefits for livestock and aquaculture systems.

5.2. Bromelain supplements

Abreu and Figueiredo (2019) highlighted pineapple residues as a promising source of bromelain, a high-value proteolytic enzyme widely used in food, cosmetics, and pharmaceuticals. It is mainly extracted from stems and crowns (Chakraborty et al., 2021; Lalhruaitluangi & Mandal, 2024). According to Kansakar et al. (2024), bromelain was first identified and studied in Europe in the late 19th century due to its proteolytic activity.

The extraction process involves crushing pineapple residues without water, followed by purification through filtration and chemical precipitation (Fissore et al., 2023). Advanced techniques like ion exchange chromatography, membrane filtration, and aqueous two-phase systems have improved bromelain’s purity and activity, supporting its industrial use. It is later formulated into capsules, soluble powders, or tablets for use in dietary supplements (Abreu & Figueiredo, 2019).

In the food industry, bromelain is used to tenderize meat and improve texture in bakery products, functioning optimally at temperatures between 50 and 70ºC (Abreu & Figuereido, 2019). In the pharmaceutical sector, it is valued for its anti-inflammatory, antiedematous, and digestive properties, helping to manage gastrointestinal symptoms and reduce inflammation (Manzoor et al., 2016). In cosmetics, bromelain acts as a natural exfoliant, helping remove dead skin and improve appearance, with reported benefits against wrinkles, acne, and dryness through its proteolytic activity (Abbas et al., 2021; Kansakar et al., 2024).

Varilla et al. (2021) described bromelain as a complex mix of thiol endopeptidases and other compounds present in fruit, stem, and root. However, the highest concentrations are found in the stem and fruit, making them key targets for extraction (Fissore et al., 2023).

Bromelain supplements are popular due to their health benefits. The enzyme supports protein digestion, alleviates gastrointestinal discomfort, and has anti-inflammatory and antioxidant effects (Kansakar et al., 2024). Studies also suggest its potential in reducing edema, muscle pain, and symptoms of respiratory infections, dental conditions, and burns in children (Locci et al., 2024). Furthermore, research points to possible anticancer and antimicrobial effects (Chakraborty et al., 2021).

Given these benefits, bromelain is becoming a strategic product for adding value to pineapple residues. The global bromelain market, valued at USD 27.3 million in 2024, is expected to grow at 7.5% annually, reaching USD 56.2 million by 2024. This trend, according to Fact.MR (2024), reflects growing consumer interest in natural health products and wellness-focused supplements.

5.3. Functional feed for livestock

Converting pineapple residues into functional livestock feed offers a practical way to increase the value of agricultural by-products. Idayanti et al. (2021) describe how functional feed is produced by mixing crushed peels, crowns, and other pineapple residues with nutritional additives, and then processing the mixture into compact pellets. This format simplifies transport, storage, and use, making it suitable for small and large-scale agricultural operations.

Including pineapple residues in livestock feed provides health and productivity benefits.

The soluble and insoluble fibers present act as prebiotics, supporting gut microbiota balance, enhancing immune response, and improving nutrient absorption. Sukri et al. (2023) report that animals fed with these diets show better growth rates, higher milk yield, and improved meat quality.

This strategy supports circular economy practices by reducing agricultural waste while improving farm profitability through better feed efficiency and animal performance.

5.4. Antioxidant extracts as functional supplements

Pineapple peels contain antioxidants like flavonoids and phenolic acids that can be extracted and used in functional supplements (Nordin et al., 2023; Rabiu et al., 2018). These compounds are usually extracted with water or hydroalcoholic solutions, followed by filtration, concentration, and drying using methods such as spray drying (Lourenço et al., 2021).

Polania Rivera et al. (2023) optimized solid-state fermentation (SSF) of MD2 pineapple peels with Rhizopus oryzae (MUCL 28168). They found that a moisture level of 80%, pH 5.5, 37.3°C, and a 24-hour fermentation time led to the highest phenolic content and antioxidant activity.

Sah et al. (2016) proposed another method to make pineapple waste powder (PWP), which includes immersion in hot water (90 °C for 30 minutes) to deactivate enzymes and potential pathogens. After that, the material is dried at 60ºC, freeze-dried, milled to fine powder (under 180 μm), and sterilized with UV light for 30 minutes.

Once prepared, these extracts or powders can be encapsulated and used in supplements aimed at reducing oxidative stress and lowering risks of diseases such as cancer and heart problems (Lalhruaitluangi & Mandal, 2024; Seenak et al., 2021). Mehraj et al. (2024) also describe their nutritional and pharmacological potential, including relief from constipation and support for people with irritable bowel syndrome (IBS), as well as some anti-parasitic effects.

Antioxidant powders from pineapple residues are also used in cosmetics and functional foods. They are appreciated for improving skin appearance and slowing aging (Mohd Ali et al., 2020). This kind of product helps to close the production cycle while also adding economic value to agricultural waste.

5.5. Flour for functional human foods

Although pineapple peel and crown flour is often used in animal feed, it can also be processed safely for human consumption, offering both nutritional value and a sustainable alternative ingredient. López-Núñez et al. (2018) studied the effects of drying on the physicochemical and techno-functional properties of pineapple peel flour and concluded that drying at 50°C preserved the highest levels of protein and dietary fiber, improving its functional properties.

When properly treated through heat and sanitation steps, this flour can be included in foods like baked goods, energy bars, and powdered drinks, providing dietary fiber and important micronutrients (Damasceno et al., 2016). Campos et al., (2020) point out that these benefits support digestive health, weight control, and increased fiber intake in functional food applications.

Chong et al. (2024) observed that pineapple flour powder (PFP) helped increase the presence of beneficial gut bacteria, such as Bacteroides ovatus, B. cellulosilyticus, B. intestinalis, Bifidobacterium bifidum, Roseburia inulinivorans, and Eubacterium siraeum. This suggests that including pineapple-based ingredients in daily diets may support gut health while contributing to more sustainable food systems.

Sah et al. (2016) explored the use of pineapple waste powder in dairy products such as yogurt and found it promoted the growth of probiotics like Lactobacillus acidophilus, L. casei and L. paracasei, along with antioxidant and antimutagenic activity. Similarly, Jose et al. (2022) tested pineapple pomace powder (PPP) in wheat flour cookies. The resulting cookies had lower gluten content and better antioxidant and functional properties. Zúñiga-Martínez et al. (2022) reported that cookies containing 15 % pineapple flour received the acceptance level from consumers.

These studies show that pineapple residues can be successfully converted into valuable functional food ingredients. By transforming waste into nutritious products, this approach supports sustainability while meeting the growing demand for healthier and more environmentally responsible food options, and creating new opportunities in emerging markets.

6. Industrial and biotechnological applications

Pineapple residues are rich in bioactive compounds and lignocellulosic fibers, offering many opportunities for industrial innovation in the food, pharmaceutical, and cosmetic sectors. As Areti et al., (2024) point out, these components allow the development of high-value products that respond to sustainability goals while creating new market possibilities.

6.1. Microcrystalline cellulose

Microcrystalline cellulose (MCC) can be obtained from pineapple peel and crown fibers using a combination of chemical and mechanical processes (Sethupathi et al., 2024). The method includes an alkaline treatment with 5% sodium hydroxide (NaOH) at 70°C for 150 minutes to remove lignin and hemicellulose. After that, bleaching is done with 3% hydrogen peroxide (H2O2) at 60°C for 60 minutes. The fibers are then filtered and rinsed with distilled water until the pH is neutral (Nawangsari et al., 2024). This process produces particles with good thermal stability, gel-forming capacity, and high dispersion in liquids.

In the food industry, CC is used as a thickener, stabilizer, and anti-caking agent in sauces, desserts, and beverages (Varqani & Bastian, 2023). According to Bampidis et al. (2020), the European Commission confirmed its safety and effectiveness as a feed additive with no risks to consumers or the environment.

In the pharmaceutical sector, MCC is widely used as an excipient in tablet formulations. It helps bind ingredients, improves tablet structure, and ensures controlled release of active substances. It also provides bulk and consistency, which supports accurate dosing and improves stability and solubility (Chaerunisaa et al., 2019). Beyond these applications, MCC is also being explored for biodegradable packaging and bioplastics, expanding its relevance in sustainable material development.

6.2. Nanocellulose

Nanocellulose obtained from pineapple residues is considered a high-value material with a wide range of applications. In Costa Rica, Moreno et al. (2017) showed that microcrystalline cellulose (MCC) from pineapple waste could be converted into cellulose nanoparticles using sulfuric acid (H2SO4) at concentrations of 30% w/v and 60% (w/v). Camacho et al. (2017) used a two-step hydrolysis process: first with hydrochloric acid (HCl) to produce MCC, then with H2SO4 hydrolysis to reduce lignin content and decrease particle size. After 60 minutes of exposure to 65 wt% H2SO4, nanofiber-like structures were obtained.

Soares-Faria et al. (2020) successfully produced cellulose nanocrystals (CNCs) from pineapple crown fibers through alkali pretreatment and acid hydrolysis. This method, which included mercerization and bleaching, removed lignin and hemicellulose efficiently. The final product showed nanoparticles with an average width of 10.38 nm, confirming the viability of pineapple residues as a source for CNCs.

Fitriani et al. (2020; 2021b) worked with pineapple crown leaf fiber (PCLF) to produce nanocrystalline cellulose (NCC) using H2SO4 hydrolysis. They reported a maximum NCC yield of 79,37% in just one hour. The material had rod-like morphology, high crystallinity, and good thermal stability, suggesting its potential in various fields.

Hernández Pérez et al. (2023) reviewed nanocellulose extraction techniques from different postharvest wastes, including pineapple. They showed that NCC from pineapple crown leaves could be added to whey protein isolate (WPI) films for food packaging. According to Fritriani et al. (2021a), the inclusion of NCC improved the films’ strength, thermal resistance, and water barrier properties while slightly reducing their transparency, making them suitable for eco-friendly packaging applications.

6.3. Antioxidants extracted from peels

Agroindustrial residues like pineapple peels are a good source of antioxidant dietary fiber (ADF), which combines fiber and phenolic compounds with potential to help prevent chronic conditions such as cardiovascular disease, neurodegeneration, and type II diabetes (Angulo-López et al., 2023). Pineapple peels contain natural antioxidants including flavonoids, phenolic acids, and vitamin C, all of which possess highly beneficial bioactive properties (Valdés et al., 2021; Nordin et al., 2023). These compounds are often extracted by hydroalcoholic maceration or ultrasound-assisted extraction methods, followed by filtration and concentration, resulting in useful antioxidant-rich extracts (Lourenço et al., 2021).

In the food sector, these extracts are used to fortify functional foods and beverages that may help reduce oxidative stress, support cardiovascular health, and strengthen the immune system (Lalhruaitluangi & Mandal, 2024; Mehraj et al., 2024; Seenak et al., 2021). For instance, Roda & Lambri (2019) added pineapple peel flour to cooked meat sausages inoculated with thermotolerant lactic acid bacteria. The fiber improved water retention, reduced lipid oxidation, and changed the texture during storage, resulting in a functional meat product.

Pineapple-derived antioxidants are also used in cosmetic products like creams and lotions for skin protection from free radicals and cellular regeneration. In the pharmaceutical field, they are being studied for their role in preventing chronic diseases, including cancer and diabetes. Other reported benefits include anti-inflammatory effects, support for join health, and improved protein digestion (García-Villegas et al., 2022). Because of their multiple uses, these compounds offer value for food, health, and cosmetic industries.

6.4. Natural pectins for the food industry

Pineapple peels are a good source of natural pectin, a type of polysaccharide that can be extracted using acid hydrolysis followed by purification. Shimavathi et al. (2022) reported a maximum yield of pectin using a liquid-to-solid ratio of 15.20 mL/g, with ultrasonication for about 22 minutes, at 70.83 °C and pH 1.0. Other methods, like ultrasound-assisted hot water extraction followed by gradient ethanol precipitation, have also been used successfully (Tan et al., 2024).

These pectins act as natural gelling, thickening, and stabilizing agents and are widely used in products such as jams, jellies, yogurts, and candies. Compared to synthetic alternatives, they offer a cleaner label and respond to the growing demand for functional and natural ingredients. Pectins from pineapple peels are also being explored for applications in biopolymer films and as plasticizers in sustainable packaging (Rodsamran & Sothornvit, 2019).

Besides their role in food texture and stability, pectins provide several health benefits. According to Soomro et al. (2024), they can help lower cholesterol, support blood sugar control, and offer antioxidant, anti-inflammatory, and immune-modulating effects. Because of this, pineapple-derived pectins are gaining attention for use in health-oriented food products.

6.5. Hydrogels for biomedical and cosmetic applications

Pineapple residues can be used to produce hydrogels, which are polymeric materials known for their high-water absorption and good mechanical strength. Their adsorption capacity improves when reinforced with 10% kaolin, as shown by Aili Hamzah et al. (2021). Hydrogels can also be made by combining fiber extracts from pineapple peels or crowns with natural polymers like guar gum or starch, further enhancing their functional properties (Bashir et al., 2020).

In the cosmetic industry, hydrogels are commonly used in facial masks and moisturizers due to their ability to hydrate the skin over time, restore elasticity, and reduce signs of aging (Mitura et al., 2020). Their water retention properties make them especially useful in skin care formulations focused on hydration and texture improvement.

In biomedicine, hydrogels serve as effective wound dressings. They help maintain a moist environment that facilitates tissue regeneration and lowers the risk of infection (Yin et al., 2022).

Another innovative material derived from pineapple-based cellulose is the aerogel. These porous materials are made by removing the liquid from a gel, typically using supercritical drying. Compared to traditional silica aerogels, they offer better compressive strength and are biodegradable. According to Mishra et al. (2024), they can also function as oil/water separators or carriers for metal nanoparticles, making them useful in filtration and adsorption applications.

6.6. Essential oils from pineapple peels

Pineapple peels contain volatile compounds that can be extracted as essential oils with antibacterial, antioxidant, and anti-inflammatory properties (Nordin et al., 2023). These oils are used in several industries, including perfumery, aromatherapy, cosmetics, and food (Ibrahim et al., 2023). Among the common extraction techniques are steam distillation, solvent extraction, and supercritical fluid extraction (SFE), though steam distillation is often the most affordable option.

Mohamad et al. (2019) described a procedure using steam distillation to obtain essential oil from dried pineapple peels. After cutting and grinding, the peels were oven-dried at 60ºC for 48 hours and stored in airtight containers. For the extraction, 100 g of the dried material were mixed with 300 mL of distilled water in a 1-liter round-bottom flask connected to a Clevenger-type apparatus. The mixture was heated at 100 °C for 3 hours, allowing the vapor to carry the oils, which were later condensed and separated into essential oil and aromatic water (hydrosol). The oil yield was calculated by weight and stored in amber vials at -20ºC to preserve its quality.

These oils contain compounds like esters, aldehydes, ketones, acids, and terpenes, that give them their tropical scent and functional properties (Meena et al., 2022). In perfumery and aromatherapy, they offer exotic aromas and relaxation effects. In cosmetics, they are added to shampoos and lotions for their fragrance and antioxidant benefits (Sarkic & Stappen, 2018). In food, they are used as natural flavorings in drinks, sweets, and baked goods, offering an eco-friendly alternative to synthetic additives (Hikal et al., 2022).

6.7. Biodegradable packaging made from residues

Pineapple residues, especially lignocellulosic fibers from peels and crowns, are useful raw materials for making biodegradable packaging. These fibers can be mixed with biopolymers like starch, polylactic acid (PLA), or polyhydroxyalkanoate (PHA) to produce compostable items such as trays, cups, or food containers (Sethupathi et al., 2024).

Sukruansuwan and Napathorn (2018) showed that hydrolysates from pineapple waste, including peels and cores from the canning industry, could be used to produce polyhydroxybutyrate (PHB). Their process reached PHB levels of up 60% (w/w) without detoxification, making it efficient and cost-effective.

The general process involves crushing and cleaning the residues to obtain fibers, then combining them with biopolymers at controlled temperatures and molding them into final shapes. The resulting materials are fully biodegradable under composting conditions, unlike traditional plastics that persist for centuries (Jawaid et al., 2020).

Choquecahua Mamani et al. (2020) extracted cellulose from pineapple crowns using acid and alkaline treatments, achieving 84.7% purity. The treated cellulose exhibited better thermal stability (356ºC) and higher crystallinity (68%) than untreated fibers, making it suitable for reusable, eco-friendly food containers.

Using pineapple residues for packaging not only reduces plastic pollution but also adds value to waste materials. As noted by Gupta et al. (2024), this approach responds to the growing demand for sustainable packaging in sectors like food and logistics.

6.8. Sorbents from fibrous residues

Pineapple residues are gaining interest as low-cost, eco-friendly materials for wastewater treatment. Kainth et al. (2024) identified agricultural waste, including pineapple peels and crowns, as a promising source for biosorbents that can help remove heavy metals and dyes from polluted water. Advances in biosorption mechanisms are improving their effectiveness and making large-scale applications more feasible (Mishra et al., 2024).

Fouda-Nganga and Tywabi-Ngeva (2022) noted that various pineapple processing residues, such as peels, pomace, and cores, can be used as natural adsorbents to reduce water contamination. Their bioactive composition offers additional environmental benefits.

When thermally treated, pineapple fibers develop a porous structure than enhances their ability to absorb oil and chemical pollutants. Carbonization or thermal activation increases their surface area, making them useful for cleaning up spills and retaining toxic substances (Fouda-Mbanga et al., 2022).

These natural sorbents are particularly useful for removing pharmaceutical residues from water and soil. Unlike synthetic options, they are biodegradable, renewable, and less costly. Mkilima et al. (2024) emphasize that they also decompose safely, leaving no secondary waste behind, making them a sustainable alternative for environmental management.

6.9. Natural dyes extracted from pigments

Pineapple peels are a promising source of natural pigments that can be extracted with water, alcohol, or other organic solvents, and used as eco-friendly dyes. The process usually involves crushing the peels, macerating them in solvent, and purifying the extracts by filtration and evaporation. Vargas et al. (2019) used thin-layer chromatography to isolate nine pigment fractions from pineapple stubble and analyze them spectrophotometrically, showing this method’s potential for scale-up. These pigments, mainly carotenoids and chlorophylls, offer coloring and antioxidant benefits and represent a safer alternative to synthetic dyes, which can be harmful to health and the environment (Li et al., 2022).

Pineapple leaves are also a valuable source of chlorophyll. Roskan et al. (2022) reported yields of up to 29.52 mgL-1 using mechanical extraction, with potential applications in dye-sensitized solar cells. Abd Rahim et al. (2022) optimized the process further, reaching 693.29 mg/L after three extractions and eight hours of storage, noting that time plays a key role in improving yield.

In textiles, Jalil et al. (2020) applied a three-step mordanting process using aluminum potassium sulfate (alum), acetic acid, and sodium chloride to extract dye from pineapple leaves. The dyed wool showed strong resistance to washing, rubbing, and fading, supporting its use in sustainable fabric dyeing.

Umesh et al. (2023) also explored the use of pineapple peel as a substrate for fungal pigments. With a one-factor-at-a-time approach, they obtained a pigment yield of 0.523 ± 0.231 mg/g in eight days. These pigments had antibacterial and antioxidant activity and performed well in fabric dyeing trials.

Aruldass et al. (2015) demonstrated that liquid pineapple waste could serve as a low-cost medium for violacein production with Chromobacterium violaceum UTM5. The pigment showed a yield of 16,256 ± 400 mg/L under optimized conditions and remained stable for 30 days, with antimicrobial properties.

Natural pineapple-based dyes are already used in food products such as juices, ice creams, and sweets, where they offer bright, edible color. They are also found in cosmetics like lipsticks and eyeshadows and in textile dyeing, providing a biodegradable, chemical-free alternative (Li et al., 2022).

As Jalil et al. (2020) note, these natural dyes align with circular economy principles. They meet consumer demand for clean-label, sustainable products by converting agricultural waste into high-value colorants, reducing dependence on fossil-derived inputs.

6.10. Organic acids

Pineapple residues are a useful source of organic acids like malic, ferulic, lactic, succinic, and citric acid, which can be obtained through fermentation using green technologies (Meena et al., 2021; Rabiu et al., 2018). Among these, citric acid is particularly notable for its widespread use as a flavoring and acidity regulator in the food and beverage industries. Gupta (2020) reported that Aspergillus niger can produce citric acid effectively through solid-state fermentation. Besides food applications, these organic acids have environmental uses. Yang et al. (2020) noted heir potential in removing heavy metals from water, showing their value in sustainable water treatment systems.

Conclusions

The full valorization of pineapple cultivation residues offers a sustainable and versatile strategy to address the environmental, economic, and social challenges of intensive agriculture. This review identified key sectors where pineapple by-products can significantly advance bio-based innovation.

However, to realize the full potential of these innovations, structural barriers must be addressed. Limited access to technology, fragmented value chains, and regulatory gaps continue to affect progress. Territorial innovation platforms that connect universities, industry, and local governments, are essential to advance circular economy models.

Transforming pineapple waste into high-value products can help tropical agriculture become a model for circular bioeconomy. This approach supports several Sustainable Development Goals (SDGs), including those related to responsible production, clean energy, climate action, and rural development.

References

Abbas, S., Shanbhag, T., & Kothare, A. (2021). Applications of bromelain from pineapple waste towards acne. Saudi Journal of Biological Sciences, 28(1), 1001–1009. https://doi.org/10.1016/j.sjbs.2020.11.032

Abd Rahim, S. H., Zainol, N., & Samad, K. A. (2022). Optimization of chlorophyll extraction from pineapple plantation waste. Heliyon, 8(11), e11851. https://doi.org/10.1016/j.heliyon.2022.e11851

Abidin, A. Z., Steven, S., Fadli, R., Nabiel, M. F., Yemensia, E. V., Soekotjo, E. S. A., Rahman Setiawan, A. A., Sasongko, N. A., Rendra Graha, H. P., Abidin, T., & Putra, R. P. (2024). Influence of several physical parameters in enzymatic fermentation of vegetable and fruit waste to produce organic liquid fertilizer using MASARO technology. Results in Engineering, 23, 102567. https://doi.org/10.1016/j.rineng.2024.102567

Abreu, D. C. A., & Figueiredo, K. C. D. S. (2019). Bromelain separation and purification processes from pineapple extracts. Brazilian Journal of Chemical Engineering, 36(2), 1029–1039. https://doi.org/10.1590/0104-6632.20190362s20180417

Aili Hamzah, A. F., Hamzah, M. H., Che Man, H., Jamali, N. S., Siajam, S. I., & Ismail, M. H. (2021). Recent Updates on the Conversion of Pineapple Waste (Ananas comosus) to Value-Added Products, Future Perspectives and Challenges. Agronomy, 11(11), 2221. https://doi.org/10.3390/agronomy11112221

Akkan, S. (2023). Evaluating the Sustainability of Vegan Leather as an Eco-Friendly and Ethical Alternative to Animal-derived Leather [Master Thesis, School of Management at the Technical University of Munich].

Alejo Jeronimo, M., Arevalo De La Cruz, E. M., Brito-Vega, H., Gomez-Vazquez, A., Salaya-Dominguez, J. M., & Gomez-Mendez, E. (2023). The Production and Marketing Issues of Pineapple (Ananas comosus) under Humid Tropical Conditions in the State of Tabasco and Way-out. In M. Sarwar Khan (Ed.), Tropical Plant Species and Technological Interventions for Improvement. IntechOpen. https://doi.org/10.5772/intechopen.106499

Amores-Monge, V., Goyanes, S., Ribba, L., Lopretti, M., Sandoval-Barrantes, M., Camacho, M., Corrales-Ureña, Y., & Vega-Baudrit, J. R. (2022). Pineapple Agro-Industrial Biomass to Produce Biomedical Applications in a Circular Economy Context in Costa Rica. Polymers, 14(22), 4864. https://doi.org/10.3390/polym14224864

Angulo-López, J. E., Flores-Gallegos, A. C., Ascacio-Valdes, J. A., Contreras Esquivel, J. C., Torres-León, C., Rúelas-Chácon, X., & Aguilar, C. N. (2022). Antioxidant Dietary Fiber Sourced from Agroindustrial Byproducts and Its Applications. Foods, 12(1), 159. https://doi.org/10.3390/foods12010159

Areti, H. A., Muleta, M. D., Abo, L. D., Hamda, A. S., Adugna, A. A., Edae, I. T., Daba, B. J., & Gudeta, R. L. (2024). Innovative uses of agricultural by-products in the food and beverage sector: A review. Food Chemistry Advances, 5, 100838. https://doi.org/10.1016/j.focha.2024.100838

Aruldass, C. A., Rubiyatno, R., Venil, C. K., & Ahmad, W. A. (2015). Violet pigment production from liquid pineapple waste by Chromobacterium violaceum UTM5 and evaluation of its bioactivity. RSC Advances, 5(64), 51524–51536. https://doi.org/10.1039/c5ra05765e

Asim, M., Abdan, K., Jawaid, M., Nasir, M., Dashtizadeh, Z., Ishak, M. R., & Hoque, M. E. (2015). A Review on Pineapple Leaves Fibre and Its Composites. International Journal of Polymer Science, 2015, 950567. https://doi.org/10.1155/2015/950567

Asoba, G. N., Metuge, S., Ning, T. R., & Symbele, I. (2023). Hand-made paper produced from pineapple leaves (Ananas comosus) as a potential material for food packaging. Journal of Tertiary and Industrial Sciences, 3(1), 65–80. https://jtis-htttcubuea.com/wp-content/uploads/2024/04/Dr-ASOBA.pdf

Awogbemi, O., Kallon, D. V. V., Onuh, E. I., & Aigbodion, V. S. (2021). An Overview of the Classification, Production and Utilization of Biofuels for Internal Combustion Engine Applications. Energies, 14(18), 5687. https://doi.org/10.3390/en14185687

Ayilara, M. S., Adeleke, B. S., Akinola, S. A., Fayose, C. A., Adeyemi, U. T., Gbadegesin, L. A., Omole, R. K., Johnson, R. M., Uthman, Q. O., & Babalola, O. O. (2023). Biopesticides as a promising alternative to synthetic pesticides: A case for microbial pesticides, phytopesticides, and nanobiopesticides. Frontiers in Microbiology, 14, 1040901. https://doi.org/10.3389/fmicb.2023.1040901

Bampidis, V., Azimonti, G., de Lourdes Bastos, M., Christensen, H., Dusemund, B., Kos Durjava, M., Kouba, M., López-Alonso, M., López Puente, S., Marcon, F., Mayo, B., Pechová, A., Petkova, M., Ramos, F., Sanz, Y., Villa, R. E., Woutersen, R., Bories, G., … Aquilina, G. (2020). Safety and efficacy of microcrystalline cellulose for all animal species. EFSA Journal, 18(7), 6209. https://doi.org/10.2903/j.efsa.2020.6209

Banerjee, S., Ranganathan, V., Patti, A., & Arora, A. (2018). Valorisation of pineapple wastes for food and therapeutic applications. Trends in Food Science & Technology, 82, 60–70. https://doi.org/10.1016/j.tifs.2018.09.024

Bashir, S., Hina, M., Iqbal, J., Rajpar, A. H., Mujtaba, M. A., Alghamdi, N. A., Wageh, S., Ramesh, K., & Ramesh, S. (2020). Fundamental Concepts of Hydrogels: Synthesis, Properties, and Their Applications. Polymers, 12(11), 2702. https://doi.org/10.3390/polym12112702

Bhatia, L., Jha, H., Sarkar, T., & Sarangi, P. K. (2023). Food Waste Utilization for Reducing Carbon Footprints towards Sustainable and Cleaner Environment: A Review. International Journal of Environmental Research and Public Health, 20(3), 2318. https://doi.org/10.3390/ijerph20032318

Bohari, N., Mohidin, H., Idris, J., Andou, Y., Man, S., Saidan, H., & Mahdian, S. (2020). Nutritional characteristics of biochar from pineapple leaf residue and sago waste. Pertanika Journal Science & Technology, 28(S2), 273–286. https://doi.org/10.47836/pjst.28.S2.21

Camacho, M., Corrales, Y. R., Lopretti, M., Bustamante, L., Moreno, G., Alfaro, B., & Vega-Baudrit, J. R. (2017). Synthesis and characterization of nanocrystalline cellulose derived from pineapple peel residues. Journal of Renewable Materials, 5, 3–4. https://doi.org/10.7569/JMR.2017.634117

Campos, D. A., Coscueta, E. R., Vilas-Boas, A. A., Silva, S., Teixeira, J. A., Pastrana, L. M., & Pintado, M. M. (2020). Impact of functional flours from pineapple by-products on human intestinal microbiota. Journal of Functional Foods, 67, 103830. https://doi.org/10.1016/j.jff.2020.1038

Casabar, J. T., Unpaprom, Y., & Ramaraj, R. (2019). Fermentation of pineapple fruit peel wastes for bioethanol production. Biomass Conversion and Biorefinery, 9(4), 761–765. https://doi.org/10.1007/s13399-019-00436-y

Chaerunisaa, A. Y., Sriwidodo, S., Abdassah, M., Chaerunisaa, A. Y., Sriwidodo, S., & Abdassah, M. (2019). Microcrystalline Cellulose as Pharmaceutical Excipient. In U. Ahmad, & J. Akhtar (Eds.), Pharmaceutical Formulation Design—Recent Practices. IntechOpen. https://doi.org/10.5772/intechopen.88092

Chakraborty, A. J., Mitra, S., Tallei, T. E., Tareq, A. M., Nainu, F., Cicia, D., Dhama, K., Emran, T. B., Simal-Gandara, J., & Capasso, R. (2021). Bromelain a Potential Bioactive Compound: A Comprehensive Overview from a Pharmacological Perspective. Life, 11(4), 317. https://doi.org/10.3390/life11040317

Chaves, D. M., Araújo, J. C., Gomes, C. V., Gonçalves, S. P., Fangueiro, R., & Ferreira, D. P. (2024). Extraction, characterization and properties evaluation of pineapple leaf fibers from Azores pineapple. Heliyon, 10(4), e26698. https://doi.org/10.1016/j.heliyon.2024.e26698

Chintagunta, A. D., Ray, S., & Banerjee, R. (2017). An integrated bioprocess for bioethanol and biomanure production from pineapple leaf waste. Journal of Cleaner Production, 165, 1508–1516. https://doi.org/10.1016/j.jclepro.2017.07.17

Chong, C. W., Liew, M. S., Ooi, W., Jamil, H., Lim, A., Hooi, S. L., Tay, C. S. C., & Tan, G. (2024). Effect of green banana and pineapple fibre powder consumption on host gut microbiome. Frontiers in Nutrition, 11, 1437645. https://doi.org/10.3389/fnut.2024.1437645

Choquecahua Mamani, D., Otero Nole, K. S., Chaparro Montoya, E. E., Mayta Huiza, D. A., Pastrana Alta, R. Y., & Aguilar Vitorino, H. (2020). Minimizing organic waste generated by pineapple crown: A simple process to obtain cellulose for the preparation of recyclable containers. Recycling, 5(4), 24. https://doi.org/10.3390/recycling5040024

Damasceno, K., Alvarenga Gonçalves, C. A., Dos Santos Pereira, G., Lacerda Costa, L., Bastianello Campagnol, P. C., Leal De Almeida, P., & Arantes-Pereira, L. (2016). Development of Cereal Bars Containing Pineapple Peel Flour (Ananas comosus L. Merril). Journal of Food Quality, 39(5), 417–424. https://doi.org/10.1111/jfq.12222

Dhanda, V., Arsalan, S., Shubham, & Kaushal, S. (2024). Revolutionizing material: The rise of bio leather as eco-friendly and sustainable approach. International Journal of Research in Agronomy, 7(11), 121–128. https://doi.org/10.33545/2618060X.2024.v7.i11b.1954

Eixemberg, D., Carballo-Arce, A. F., Vega-Baudrit, J. R., Trimino-Vásquez, H., Villegas-Peñaranda, L. R., Stöbener, A., Aguilar, F., Mora-Villalobos, J. A., Sandoval-Barrantes, M., Bubenheim, P., & Liese, A. (2024). Tropical agroindustrial biowaste revalorization through integrative biorefineries. Review Part II: pineapple, sugarcane and banana by-products in Costa Rica. Biomass Conversion and Biorefinery, 14, 4391-4418. https://doi.org/10.1007/s13399-022-02721-9

Fact. MR. (2024). Bromelain Market (FACT9158MR. Food & Beverage). Market Research Survey. https://www.factmr.com/report/bromelain-market

FAOSTAT (2024). Crops and Livestocks Products. Food and Agriculture Organization of the United Nations. https://www.fao.org/faostat/en/#data/QCL

Fernandes Pereira, P. H., Ornaghi Junior, H. L., Arantes, V., & Hilário Cioffi, M. O. (2021). Effect of chemical treatment of pineapple crown fiber in the production, chemical composition, crystalline structure, thermal stability and thermal degradation kinetic properties of cellulosic materials. Carbohydrate Research, 499, 108227. https://doi.org/10.1016/j.carres.2020.108227

Figge, F., Thorpe, A. S., & Gutberlet, M. (2023). Definitions of the circular economy: Circularity matters. Ecological Economics, 208, 107823. https://doi.org/10.1016/j.ecolecon.2023.107823

Fissore, A., Marengo, M., Santoro, V., Grillo, G., Oliaro-Bosso, S., Cravotto, G., Dal Piaz, F., & Adinolfi, S. (2023). Extraction and characterization of bromelain from pineapple core: A strategy for pineapple waste valorization. Processes, 11(7), 2064. https://doi.org/10.3390/pr11072064

Fitriani, F., Aprilia, S., Arahman, N., Bilad, M. R., Suhaimi, H., & Huda, N. (2021a). Properties of biocomposite film based on whey protein isolate filled with nanocrystalline cellulose from pineapple crown leaf. Polymers, 13(24), 4278. https://doi.org/10.3390/polym13244278

Fitriani, F., Aprilia, S., Arahman, N., Bilad, M. R., Amin, A., Huda, N., & Roslan, J. (2021b). Isolation and characterization of nanocrystalline cellulose isolated from pineapple crown leaf fiber agricultural wastes using acid hydrolysis. Polymers, 13(23), 4188. https://doi.org/10.3390/polym13234188

Fitriani, Aprilia, N. A. S., & Arahman, N. (2020). Properties of nanocrystalline cellulose from pineapple crown leaf waste. IOP Conference Series: Materials Science and Engineering, 796, 012007. https://doi.org/10.1088/1757-899x/796/1/012007

Fouda-Mbanga, B. G., & Tywabi-Ngeva, Z. (2022). Application of pineapple waste to the removal of toxic contaminants: A review. Toxics, 10(10), 561. https://doi.org/10.3390/toxics10100561

Frimpong, K. A., Abban-Baidoo, E., & Marschner, B. (2021). Can combined compost and biochar application improve the quality of a highly weathered coastal savanna soil? Heliyon, 7(5), e09089. https://doi.org/10.1016/j.heliyon.2021.e07089

García-Villegas, A., Rojas-García, A., Villegas-Aguilar, M. del C., Fernández-Moreno, P., Fernández-Ochoa, Á., Cádiz-Gurrea, M. de la L., Arráez-Román, D., & Segura-Carretero, A. (2022). Cosmeceutical potential of major tropical and subtropical fruit by-products for a sustainable revalorization. Antioxidants, 11(2), 203. https://doi.org/10.3390/antiox11020203

Gomes dos Reis, C., Feitosa de Figueirêdo, R. M., de Melo Queiroz, A. J., Ferreira Paiva, Y., Santos Amadeu, L. T., Suelia dos Santos, F., de Lima Ferreira, J. P., Bezerra de Lima, T. L., Santos Andrade, F., Palmeira Gomes, J., Pereira da Silva, W., & da Costa Santos, D. (2023). Pineapple peel flours: Drying kinetics, thermodynamic properties, and physicochemical characterization. Processes, 11(11), 3161. https://doi.org/10.3390/pr11113161

Gunawardena, M. A., & Lokupitiya, E. (2024). Comparison of conventionally and organically grown pineapple in Sri Lanka: An integrative approach applying life cycle assessment and externalities. Cleaner Environmental Systems, 14, 100219. https://doi.org/10.1016/j.cesys.2024.100219

Gupta, M. (2022). Pineapple waste utilization: wealth from waste. The Pharma Innovation Journal, SP-11(6), 1971–1978. https://www.thepharmajournal.com/archives/2022/vol11issue6S/PartY/S-11-6-101-345.pdf

Gupta, R. K., Ali, E. A., El Gawad, F. A., Daood, V. M., Sabry, H., Karunanithi, S., & Srivastav, P. P. (2024). Valorization of fruits and vegetables waste byproducts for development of sustainable food packaging applications. Waste Management Bulletin, 2(4), 21–40. https://doi.org/10.1016/j.wmb.2024.08.005

Hanyabui, E., Frimpong, K. A., Annor-Frempong, F., & Atiah, K. (2024). Effect of pineapple waste biochar and compost application on the growth and yield of pineapple varieties in Ghana. Frontiers in Agronomy, 6, 1331377. https://doi.org/10.3389/fagro.2024.1331377

Hemung, B. O., Sompholkrang, M., Wongchai, A., Chanshotikul, N., & Ueasin, N. (2022). A study of the potential of by-products from pineapple processing in Thailand: Review article. International Journal of Health Sciences, 6(S4), 12605-12615. https://doi.org/10.53730/ijhs.v6nS4.12131

Hernández Pérez, R., Álvarez Castillo, A., Olarte Paredes, A., & Salgado Delgado, A. M. (2023). Obtención de nanocelulosa a partir de residuos postcosecha. Mundo Nano. Revista Interdisciplinaria en Nanociencias y Nanotecnología, 16(30), 1e-47e. https://doi.org/10.22201/ceiich.24485691e.2023.30.69662